McDonough & BID Canada launch patent-pending modular conveyor system.

McDonough Manufacturing

Precision Engineered Sawmill Equipment & Material Handling

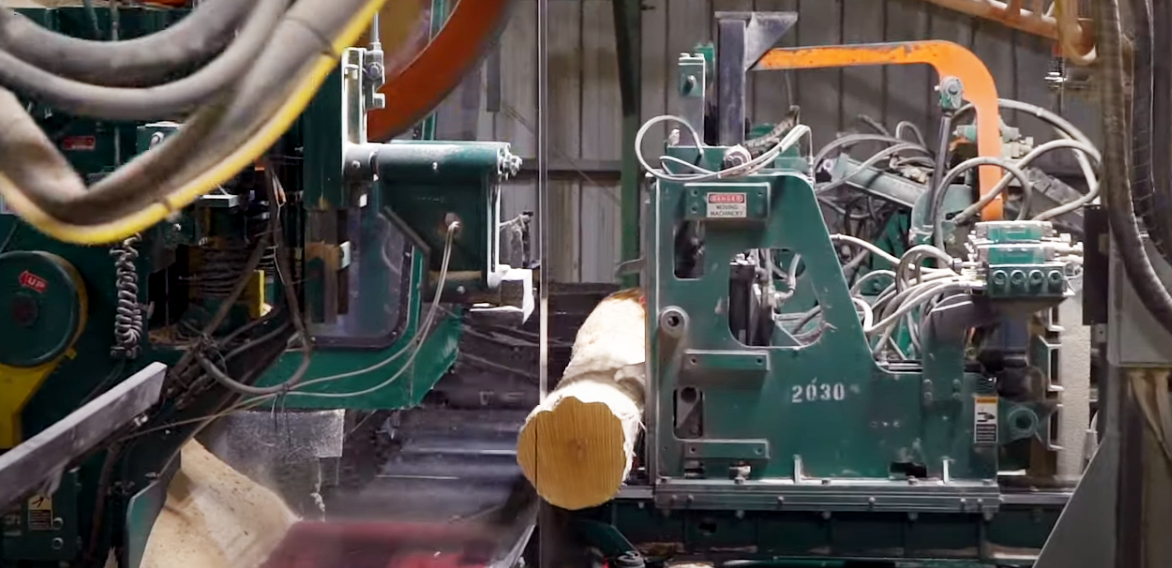

Since 1888, McDonough Manufacturing has led the forest products industry with rugged, efficient sawmill machinery. From double-column bandmills and optimized edger systems to resaws, carriages, gang sawing, and custom material handling solutions, our equipment is built for uptime, yield, and reliability.

Before investing in capital equipment, make sure you are asking the right questions. This buying guide helps mills plan smarter, reduce risk, and avoid costly surprises.

Our Products

Board Edgers

Bandmills

Double-column, Air‑Strain bandmills range from 54″ to 96″ throat, featuring cartridge-type pressure guides, cast iron wheels, hydraulic lifts, saw cleaning systems, and heavy-duty construction. These mills consistently outperform legacy competition.

Resaws

We offer everything from classic Linebar and Center‑Split models to high-speed automated headrigs and modular horizontals. Includes computerized setworks, operator cabs, and high-speed infeeds built for modern production lines.

Carriages

Available in 36″, 42″, and 48″ openings, McDonough carriages come with features like slanted beds, UHMW cant kickers, manual and chain turners, computerized setworks, and cab options—designed for precision and low maintenance.

Gangs

Engineered for maximum yield, our gang edgers include curve‑sawing configurations for crooked hardwood logs and thin‑kerf models for softwood production—plus combo units that handle both boards and cants in one frame.

Material Handling

From transfer decks to the MAXX Resaw Infeed—the fastest linebar feed in the industry—our engineered material handling systems support McDonough equipment or retrofits of other brands, improving mill flow and throughput.

About

Our Legacy & Capabilities

Trusted Legacy Since 1888

Founded in Eau Claire, Wisconsin, McDonough’s patented Linebar Resaw design set early industry standards. Now in its fifth generation of family ownership, the company remains committed to quality, innovation, and performance.

North American Reach with Local Expertise

In 2017, we expanded into Canada with a new manufacturing facility in Mactaquac, New Brunswick. In 2023, the acquisition of BID Canada Ltd. added depth to our material handling capabilities. Our Canadian operations are now headquartered in Woodstock, NB.

Engineering & Service You Can Trust

From design and fabrication to assembly, testing, and commissioning—every machine is built in-house. Our team offers turnkey installations, rebuilds with warranty, and ongoing service and support to keep your mill running strong.

Why McDonough

-

Built to Last: Decades of proven durability and continuous improvement

-

Proven Efficiency: Air-Strain systems, linebar feeds, and optimized cutting for minimal waste

-

Custom Solutions: Engineered for hardwood, softwood, new installations, or retrofits

-

Long-Term Support: Factory rebuilds, parts and service programs, and expert engineering consultation

Ready to Grow Your Mill?

-

Contact our team today to explore solutions, request a quote, or download product specifications.

Locations

Eau Claire, Wisconsin • Woodstock, New Brunswick, Canada

Featured

McDonough acquires BID Canada

In early 2023, McDonough expanded our Canadian footprint by acquiring BID Canada Ltd., experts in material handling. This acquistion has built on our knowledge of material handling, and provided us with increased capacity for both team members and square footage.

Projects

Work and people we can be proud of.

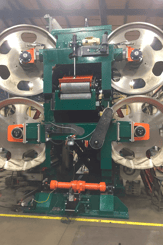

Building for Growth: A 6 Foot Quad Band Mill for Two Rivers Lumber

Work continues in the Eau Claire shop on a 6 foot Quad Band Mill being built for Two Rivers Lumber Company, a Southern Yellow Pine producer that is in the midst of a significant mill expansion in Alabama.

Efficiency at the Heart of the Mill: Where Mechanical Design Meets Profitability

In every sawmill, profit starts long before the first board is cut. It begins with design, how the equipment is built, how materials move through the line, and how easily operators can keep everything running at its best.

Bridging Tradition and Innovation in the Lumber Industry... one TikToker at a time

The lumber industry is one of the oldest in North America. It was built on hard work, craftsmanship, and pride in doing things the right way. But like every great industry, it continues to evolve.

Big Capabilities, Local Service: Why Our Shop Is Built for Projects of All Sizes

At our shop in Woodstock, New Brunswick, we’ve earned a reputation for building full-scale machines and industrial systems. But not every job that comes through our doors is massive.

Building on Shared Values: McShan Lumber and McDonough Manufacturing Partnership

At McDonough Manufacturing, we are proud to collaborate with McShan Lumber, a family-owned business dating back to 1907. A southern yellow pine mill in Alabama, McShan has a long-standing tradition of quality, innovation, and customer satisfaction. We’re excited to support McShan with the...

Testimonials

What our clients say

"It’s (OptiFit edger) a very fast and accurate machine that is easily handling the production from our 7 ft resaw and 8' headrig while yielding us far more value from our lumber."

Greg Wells

McDonough products are "well built, productive and (they) provide exceptional post-sale service"

Ray Tharpe

As a result of the upgrade, we "have significantly improved mill uptime and created a much better work environment for our Operator."

Tyler King

Newsletter

Sign Up Now

.png?width=1097&height=600&name=optifit2%20(1).png)