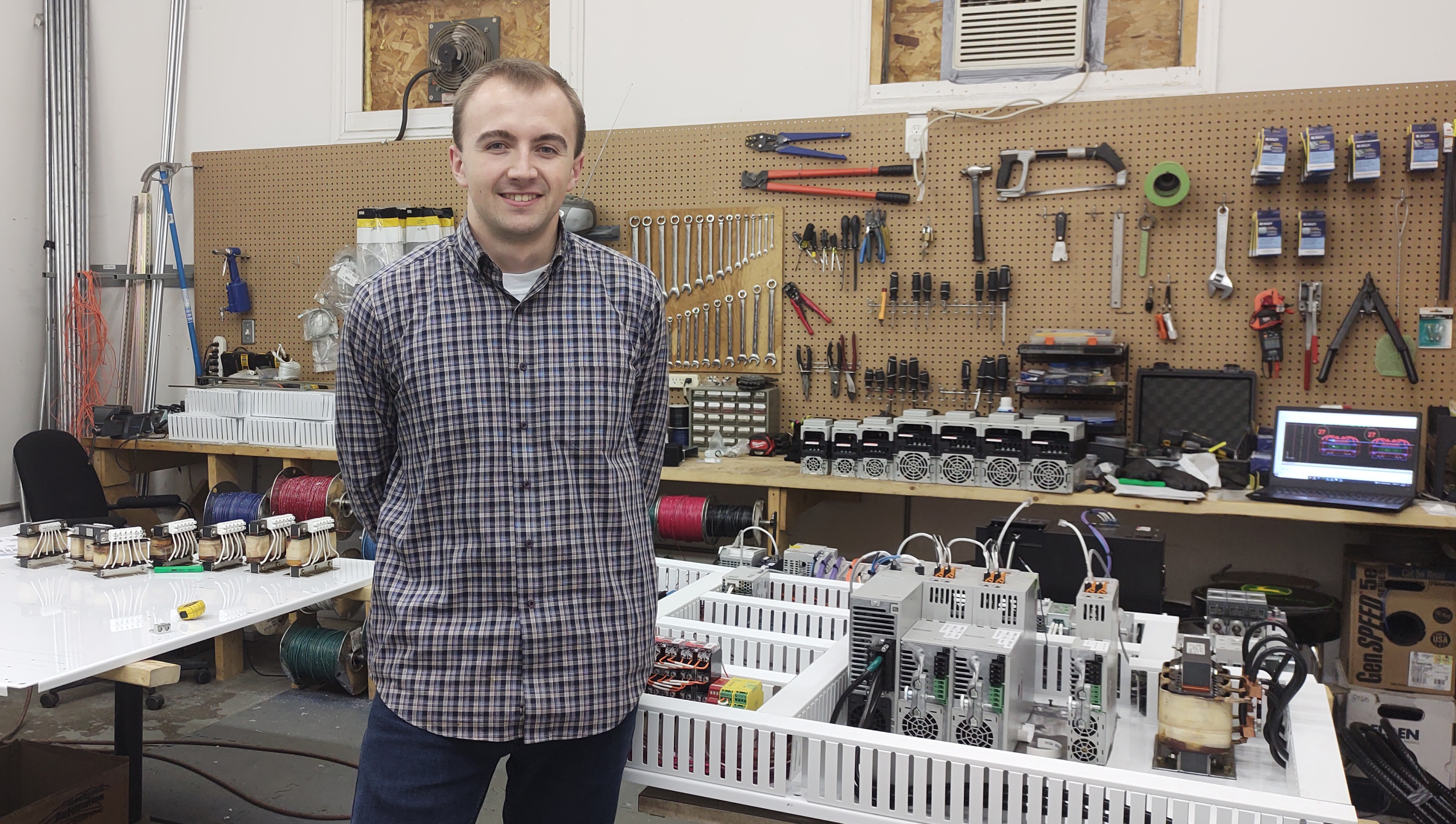

Welcoming Thomas Ryan to McDonough Canada

McDonough Canada recently welcomed new electrical engineer, Thomas Ryan, to the team. Learn more about his interests, his time in Cyprus as part of a military family, and his role at McDonough.

Posts by:

McDonough Canada recently welcomed new electrical engineer, Thomas Ryan, to the team. Learn more about his interests, his time in Cyprus as part of a military family, and his role at McDonough.

It doesn’t take long when speaking with anyone at Elmsdale Lumber Company (ELCO) or browsing their website to learn that one of the foundational principles at ELCO is their commitment to the lifelong learning of their employees. McDonough is fortunate enough to have kickstarted various projects with ELCO recently, and through our conversations over the last number of months, we began to hear about something called ‘Mel’s Story’.

The Sterling YieldBoss Hybrid Edger System is a revolutionary new approach to edging that combines the benefits of optimized saw placement with the simplicity of a manual edger system. An affordable system in a whole new class of edgers created by McDonough, a Sterling YieldBoss Hybrid Edger fits in the space between our line of McDonough fully optimized edgers that return the highest yields, and manual edgers that leave everything up to your operator.

Ryan Hemauer is a machinist in our Eau Claire shop, who brought a wealth of experience, education and a strong work ethic along with him. Learn more about his work experience and advice to future machinists in our one-on-one interview.

Just how long do McDonough resaws run? McDonough has just completed the rebuild of a 54” center split resaw we manufactured in 1970.

The driving force behind McDonough is our team – the folks in the shop and offices every day who have made it possible to produce high-quality machinery for over 130 years. Right alongside us throughout our success are the industry partners who help with our equipment installations and service calls all over the continent and world. Chief among these valued colleagues is Ray Tharpe of RTM Industrial Maintenance (RTM), who we have worked with in one capacity or another for almost 20 years.

In January 2021, Meherrin River Forest Products in Macon, North Carolina installed a new McDonough 6-7A Band Mill. Replacing an existing circle saw, this piece of equipment will allow them to reduce their kerf and increase their yield to make more lumber and less sawdust.

In a previous blog, we outlined the components of a linear edger system and their intended purpose. Now, we’ll take a look at the alignment and calibration of your linear edger.

To refresh, a linear edger operates under the basic principle that we can scan a piece of lumber while it is in one location and then ‘edge’ it when it reaches another, without handling it in between, by accurately predicting where it is going to be throughout the process.

McDonough's white paper on ‘Maximizing performance of Linear Edger Systems’, written by VP Operations Hugh Hawley over 10 years ago, has become an incredibly popular document for customers and competitors alike on how to achieve optimal linear edger performance. Today we will examine the components of a linear edger system and their overall contribution to the performance of your linear edger. In the next blog post, we will examine alignment and calibration.

Joe (dad) and Dillon (son) Chapman both work in McDonough’s Canadian shop. The pair have a lot in common, a passion for the manufacturing industry, hunting and the outdoors, but working on the shop floor with your father/son can also have some challenges. One thing they always agree on, however, is their commitment to building the best machines possible.