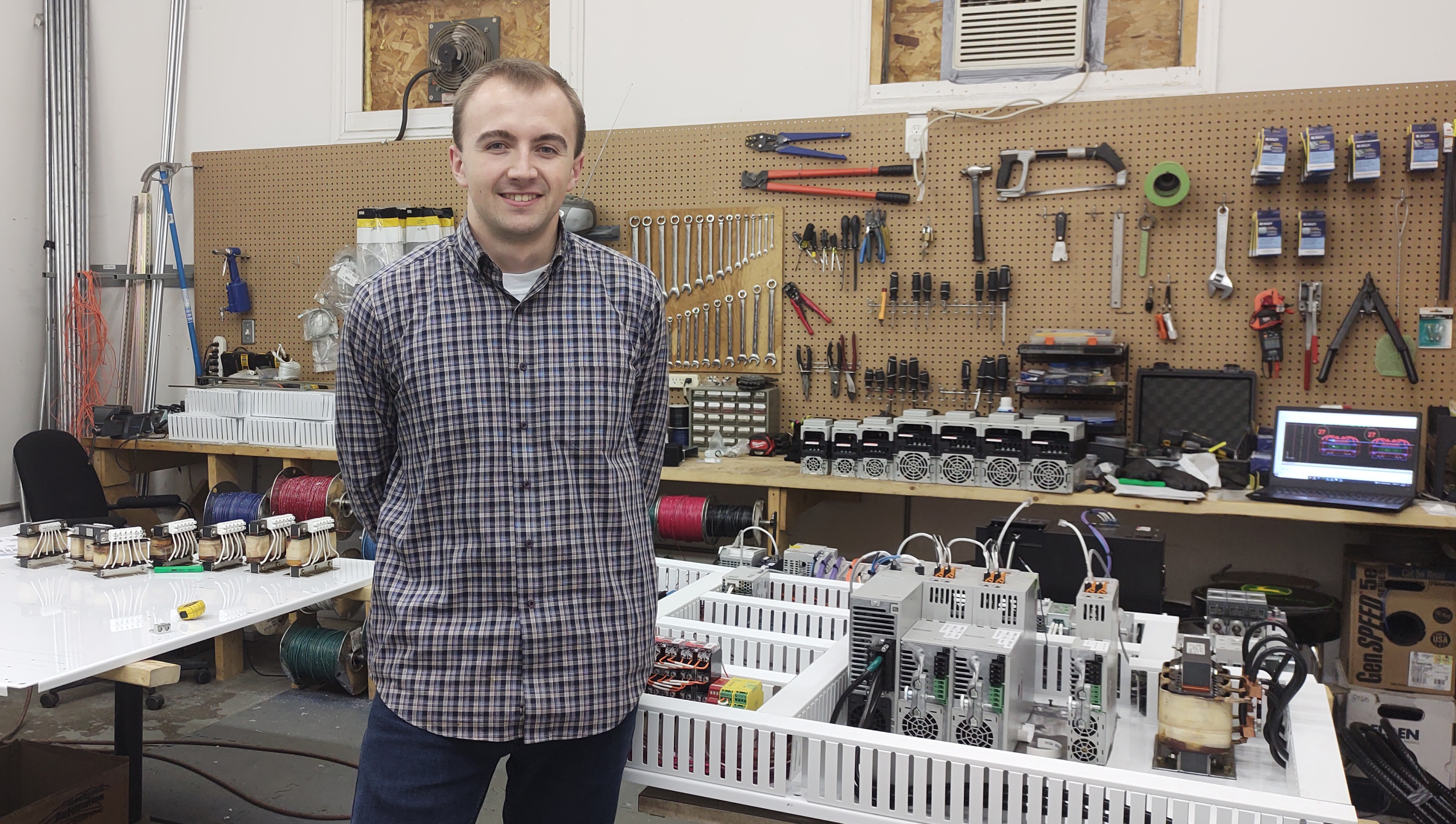

Peter Grant - McDonough, Maple Syrup and Christmas Trees

Peter Grant is a man of many talents. Having been with us at McDonough Canada since our launch in 2017, Peter is the painter responsible for applying the trademark McDonough yellow and green to our equipment. One of Peter’s greatest strengths is his versatility; in addition to painting, he can operate every machine in our shop, and works on the assembly of our equipment before helping load it onto the truck and sending it out the door. Enjoying variety in his work, Peter embraces and enjoys the new challenges that he faces each day.