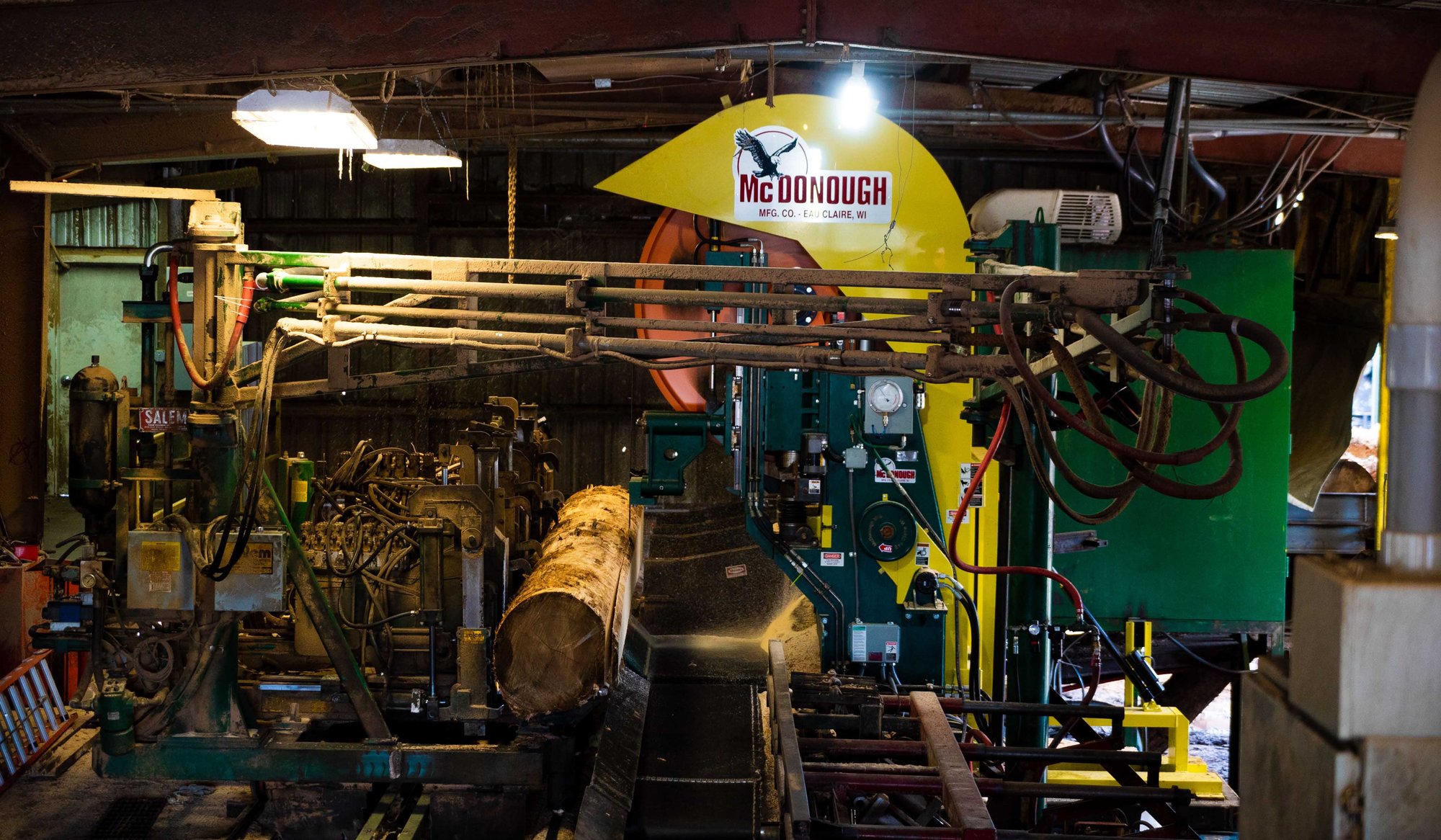

Band Mills

Since 1888, McDonough has been known as the bandmill company in the lumber industry, that's why you see McDonough headrigs in more mills than any other brand. From 54" to 8', our double column air strain mills set the standard all others are compared to. With time tested standard features like our exclusive Air Strain system, cartridge type pressure guides, cast iron wheels, hydraulic wheel lifts, saw cleaning and lubrication and Timken railroad car bearings, the McDonough bandmill simply outlasts and out performs all others.

McDonough Band Mills

The Industry’s leading Band Mill manufacturer for over 100 years! You will see a McDonough in more mills than another other brand.

Benefits:

-

Double Column frame constructed from heavy-duty plate steel. Independent column and base.

-

Exclusive McDonough Air Strain is the simplest, most effective system to increase feed speeds and minimize mis-cut lumber.

-

Cartridge Type Pressure Guide System assists in faster feed speeds and increased accuracy. Guide Block Dressing Machine to resurface guides is included with each Band Mill.

-

Cast Iron Wheels. Preferred by saw filers because they prevent saw blades from getting hot and losing tension, unlike steel wheels.

-

Other standard features: Hydraulically operated top guide and top wheel lift, Timken railroad car bearings in lower wheel, saw blade cleaning and lubricating device.

Specs:

- 54" — 12,500 pounds. 8" wide x 30' long saw blades. 75 to 125 HP required.

- 62" — 18,000 pounds. 10" wide x 36' long saw blades. 150 HP required

- 6' — 25,000 pounds. 12" wide x 40' long saw blades. 200 HP required.

- 7' — 35,000 pounds. 14" wide x 47' long saw blades. 250 HP required.

- 8' — 44,000 pounds. 14" wide x 52' long saw blades. 300 HP required.

Custom saw lengths can be accommodated upon request.